|

Leachate collection |

|

University of Padua IMAGE Department |

|

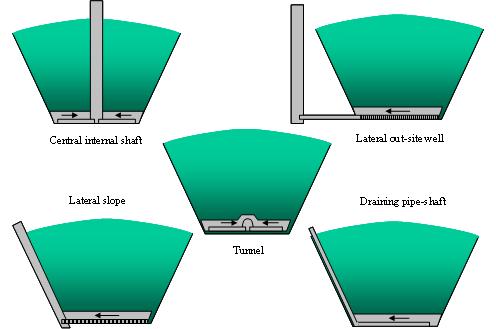

v Design strategies are addressed to minimize the transport of contaminants through the barriers to the environment. v Drainage and collection systems are essential components in a containment landfill and can be considered as a barrier. v When efficient they prevent leachate buildup and consequently decrease potential leakage to groundwater through the low permeability bottom liner. Different possible configurations for leachate extraction wells |

|

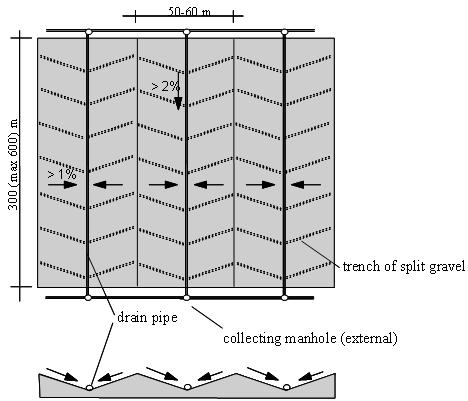

Engineering options to be employed for leachate collection a) Drainage • saw tooth configuration for the landfill bottom • good longitudinal slope (> 2%) • minimum cross slope of 1% (23% is desirable) • use, at least for MSW landfills, of only granular material (gravel) • high porosity of drainage layer • thickness of the drainage layer > 50 cm • clean gravel, possibly round shaped • high grain size which is compatible with filter stability • aerial distribution of the drainage. The filter should cover the entire area of the landfill bottom and slope • split gravel trenches suitable for a drainage layer of fine material should be placed at a distance of 15 - 20 m and should have a minimum width of 2m • avoidance of the use of any filter material (such as geotextiles) to "protect" the drainage from clogging. They actually protect the filter too well! b) Drain pipes • short space between drain pipes (50 - 60 m) • parallel straight line layout of drain pipes • pipes should be accessible from outside the waste deposit • pipe diameter should be larger than 200 mm • pipeline should be designed according to a good pressure distribution under the given conditions • reinforced drain pipe should be consequently adopted • drain pipes should be controlled by a videocamera immediatly after implacement of the first waste lift. Mechanical failure caused by compaction can be easily repaired at this stage. • regular flushing of drain pipes shoul be carried out as soon as possible as clogging deposits can be removed before concreting • process enhancement, as discussed earlier, has a positive effect on the efficiency of drainage layer as the methanogenic leachate proved to be less clogging (Ramke,1989; McBean et al.,1993). |

|

Drainage clogging |

|

Leachate accumulation |