|

Estimation of maximum LFG yields |

|

University of Padua IMAGE Department |

|

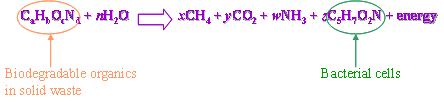

The reaction representing the overall methane fermentation process for organics in solid waste can be represented by the following by the following equation: |

|

(1) |

|

The fraction of the organic matter that is converted to biomass, considering an infinite retention time in the system, is about 4% (EMCON, 1980). Therefore, for the practical evaluation of the maximum theoretical LFG yield, cell conversion of organic matter can be neglected, and equation (1) becomes: |

|

(2) |

|

Equation (2) states that 1 mol of organic carbon is bioconverted to 1 mol of landfillgas. |

|

1 mol C org. = 1 mol (CH4 + CO2) 1 mol C in organic matter = 22,4 l (CH4 + CO2) 1 g C in organic matter = 1,867 l (CH4 + CO2) CH4 = 0,55-0,6 1,867 l |

|

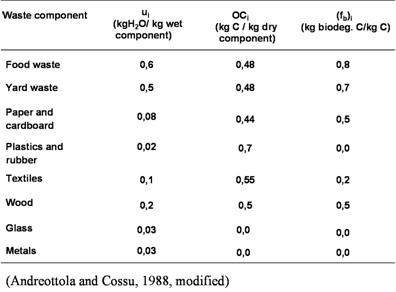

Content of biodegradable organic carbon: |

|

(OCb)i = OCi(fb)i • (1-ui) • pi |

|

The fraction of bioconvertible carbon to landfill gas depends upon the temperature within the landfill: |

|

(OCb)i = OCi (0,014 T + 0,28) |

|

Temperature, however, primarily affects generation rates, which are strictly associated with the biological activity within the landfill. |

|

LFG specific yield: |

|

LFG generation rates: The general equation that rules the biogas production is: |

|

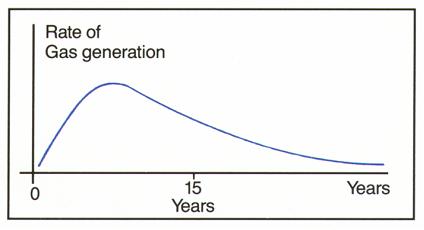

The greatest absolute exponent n of the dependent variable (C) is called the order of the model (i.e. order of kinetics). A zero-order kinetics means that a small increment (positive or negative) of C does not influence the rate of substrate decay or biogas production. According to some authors, many landfills have a biogas production that follows a zero-order kinetics, especiallly during the periods of highly active gas generation. The majority of LFG production models follow a first-order kinetics, which means that the limiting factors is the remaining amount of substrate or the amount of biogas already produced. Generation time: Satisfasfactory information concerning generation time is provided by the half time (t½), the time over which the gas generation equals half of the estimated yield. By definition the t½ is such that the area under the production curve is the same on both sides. The range of values proposed for t½ is very wide, from 2-5 years foe wet to 10-25 years for dry climates (Augenstein and Pacey, 1991). The half time can be also calculated in first-order kinetic models by the following expression: |

|

Lag time: Is the time that passes from the placement of waste to the beginning of significant gas production. Lag time can vary from a few weeks and months to 1 year and more. LFG for how long? |

|

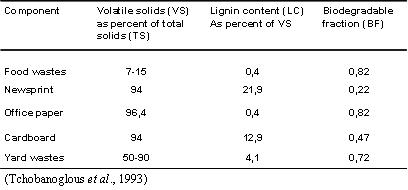

(OCb)i = biodegradable organic carbon in the ith component of waste (kg biodegradable carbon/kg wet MSW) OCi = organic carbon content in the dry ith component of waste (kg carbon/kg dry i component) (fb)i = biodegradable fraction of OCi (kg biodegradable carbon/kg carbon) ui = moisture content of the ith component of waste (kg water/kg wet i component) pi = wet weight of the ith component of waste (kg i component/kg MSW) (fb)i = 0,83 – 0,028 LC (on a volatile solids basis) LC = lignin content of the volatile solids expressed as % of dry weight |