|

Construction |

|

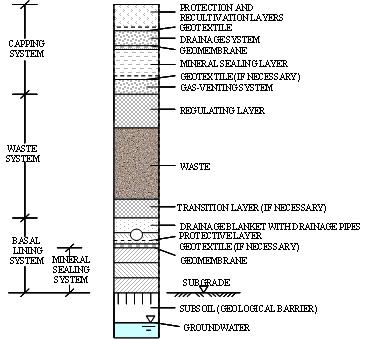

Lining systems The preparation of geotechnical design must generally examine the following: design aspects of safety components: • subsoil as a site barrier • basal lining system • waste body (including any inserts) • capping system • disposal site environment • geotechnical aspects of site operation • geotechnical concerns regarding the removal of gas and leachate liquid from the landfill • geotechnical aspects of recultivation • site closure and subsequent aftercare measures • supervision and long-term monitoring. Possible landfill components |

|

(H. L. Jessberger, 1994) |

|

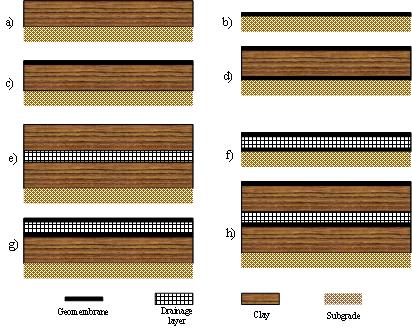

Structure of the barrier system a) Single liner of natural material (low permeability soil) this configuration represents the simplest lining system still most widely adopted, although it is considered accettable only under specific and fully safe hydrological situations. b) Single liner of synthetic material (geomembrane) a single geomembrane in the case of waste containment does not afford any safety guarantee and may be used only under conditions similar to those mentioned for a) . c) Single composite liner (clayey soil + geomembrane) this structure is the most widely recommended for municipal solid waste (MSW) landfilling and is included in the guidelines of many industialized countries. The safety level concerned is hard to predict and is of course controversially discussed. Nowadays for MSW landfilling a minimum clay liner thickness of 1 m is deemed necessary with a maximum permeability of 10-9 m s-1. Mineral liners along slopes are often substituted by a geotextile-bentonite composite although many designers still prefer clay even under these condition. d) Single composite liner (geomembrane + clayey soil + geomembrane) this configuration increases the safety level of the single composite liner and can prevent dessication and cracking of the mineral liner. The installation of this system can be critical with regard to the emplacement technique and stability behaviour when the landfill is sited on a slope. When compared to single liners, composite liners present significant benefits with regard to the amount of leachate which may migrate through the system even in the presence of holes in the geomembrane. e) Double liner of natural material this configuration, which is rarely used, foresees the installation of separation material (such geotextiles) between the mineral layers and the drainage layers. f) Double liner of synthetic material the double synthetic liner has often been proposed, particularly for the side barrier systems. Synthetic materials, such as geonet, can be conveniently adopted. The efficiency of this configuration is severely influenced by the quality of the installation and long-term behaviour of the geomembranes. g) Double semicomposite liner (double synthetic top liner+single ntural liner this structure tends to couple the advantages of the single compoite liner and the double synthetic liner, thus providing further safety level. Global efficiency still depends on the long-term behaviour of the geomembrane. h) Double composite liner this configuration fully exploits the possibility of a control drainage for the double lining system. It is the most expensive solution and nowadays is adopted mainly for industrial waste lndfill. The interest for MSW landfill applications is, however, increasing in order to minimize any adverse environmental impact. |

|

(T. H. Christensen et al., 1994) |

|

University of Padua IMAGE Department |